Working advantages of HZS180 concrete mixing plant:

1. The mixing quality is good and the uniformity is good. It can achieve good mixing in a short period of time for dry hard, semi dry hard, plastic and various mix proportions of concrete.

2. Multiple layout modes can be selected according to local conditions to adapt to various complex working conditions.

3. The overall structure is atmospheric, with quick disassembly and easy transportation.

4. Accurate measurement provides convenient conditions for the production of high-quality concrete.

5. Sealed design and configurable dust removal equipment to reduce dust and noise pollution, promoting green and environmentally friendly production.

Main Technical Parameters:

| Parameter | Value |

|---|---|

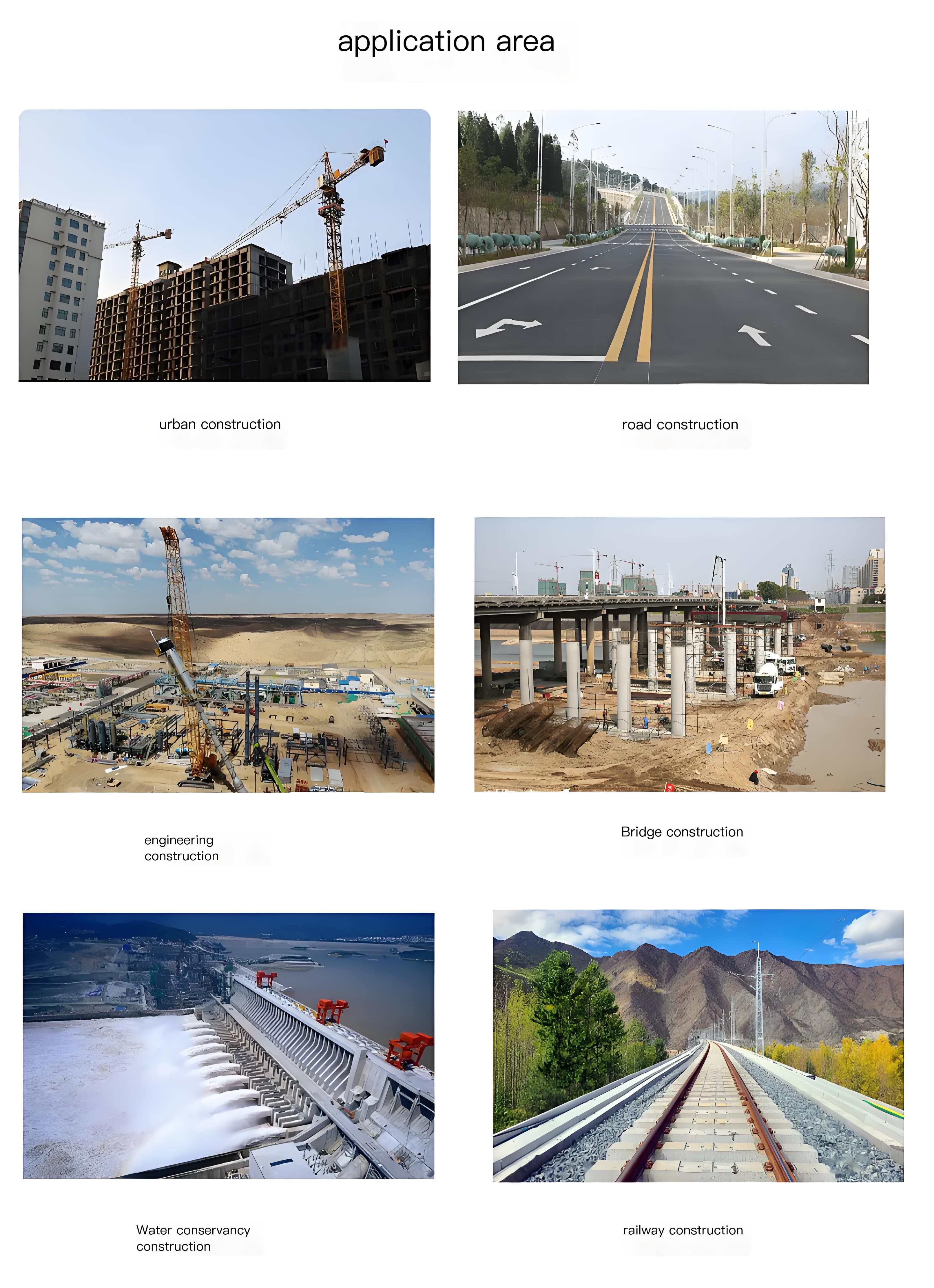

| Product Use | Road and bridge, construction, water conservancy projects |

| Theoretical Productivity | 180m³/h |

| Mixing Host | js3000 |

| Maximum Aggregate Size | 80mm |

| Aggregate Bin Volume | 4×18m³ |

| Aggregate Conveying Method | Flat belt conveyor |

| Aggregate Measurement | 2×4000kg ±2% |

| Cement Measurement | 1800kg ±1% |

| Fly Ash Measurement | 800kg ±1% |

| Water Measurement | 800kg ±1% |

| Additive Measurement | 50kg±1% |

| Total Power | 205kw |

| Machine Weight | 77t |

| Overall Dimension | 58.5m×7m×12.9m |

| Discharge Height | 3.8m |

Hzs180 mixing plant configuration list:

1. Ingredient system, 1 set of 4x18m ³ aggregate bin, 4 aggregate measuring bins, 2 sets of weighing sensors, 1000 mm wide aggregate output belt conveyor (with cleaner), 1 set of cylinders, 4 vibrators, and 2 frames.

2. Aggregate lifting system, 1.2-meter-wide flat belt 1200mm wide, 1 set of 45kw motor, 1 shaft mounted reducer, 1 drop weight tensioning device, 1 set of cleaning device, 1 set of upper and lower rollers, 1 set of double aisle rack, and 1 set of color steel plate packaging.

3. Mixing host system, 1 set of JS3000 steel structure, 2 reducers, 55kw motor, 2 unloading systems, 1 set of lubrication system, 1 set of shaft end main seal.

4. Mixing main building: 1 set of finished material receiving hopper, 1 set of mixing layer, 1 set of measuring layer, 1 set of transition material bin, 1 set of roof, 1 set of staircase walkway, 1 set of external packaging, 2 sets of vibrators, 1 set of dust removal system inside the building, and cylinder si-125-2001 pieces High pressure cleaning system sl40a1 set

5. Water metering system, 1 set of water metering tank, 3 water scales, 1 set of butterfly valve, 2 hot water pumps, and 1 pipeline

6. Cement measuring system, 1 set of measuring bin, 3 weighing sensors, 1 butterfly valve, and 1 vibrator

7. Fly ash metering system, 1 set of metering bin, 3 weighing sensors, 1 butterfly valve, and 1 vibrator

8. Additive metering system, 1 set of additive metering box, 2 sets of pipelines, 1 weighing sensor, 2 sets of pipelines, 1 butterfly valve, and 2 additive pumps

9. Pneumatic system, 1 set of solenoid valve for air compressor (complete set), 1 set of piping system, 1 set of 2 air storage tanks

10. Strong electronic control system, 1 set of electrical cabinet, 1 set of weak current cabinet, 1 set of control console, 1 set of control room, 2 sets of management control machines, 2 sets of LCD displays, 1 set of contactor, 1 set of automatic switch, 1 set of micro relay, 1 set of thermal relay, PLC 1 set, 1 set of weighing transmitter, UPS 1 set, 1 set of air conditioning, 1 set of electronic control accessories, 2 sets of monitors, 2 sets of cameras, 1 set of printer, 1 set of connecting cables and accessories

11. Powder supply system (optional for users), with 273 fly ash spirals and 323 cement spirals. The size and quantity of the powder tanks can be customized according to individual requirements

● The total power does not include the power of the screw machine;

● According to user needs, non-standard design can be carried out;

● Participating materials include fly ash, mineral powder, expansion agent, etc;

● Due to design improvements, the above parameters may change, and the product shall prevail.

Tips:Our company also offers other models, including HZS75, HZS100 and HZS120.