Which is better, a bending machine or a hoop bending machine?

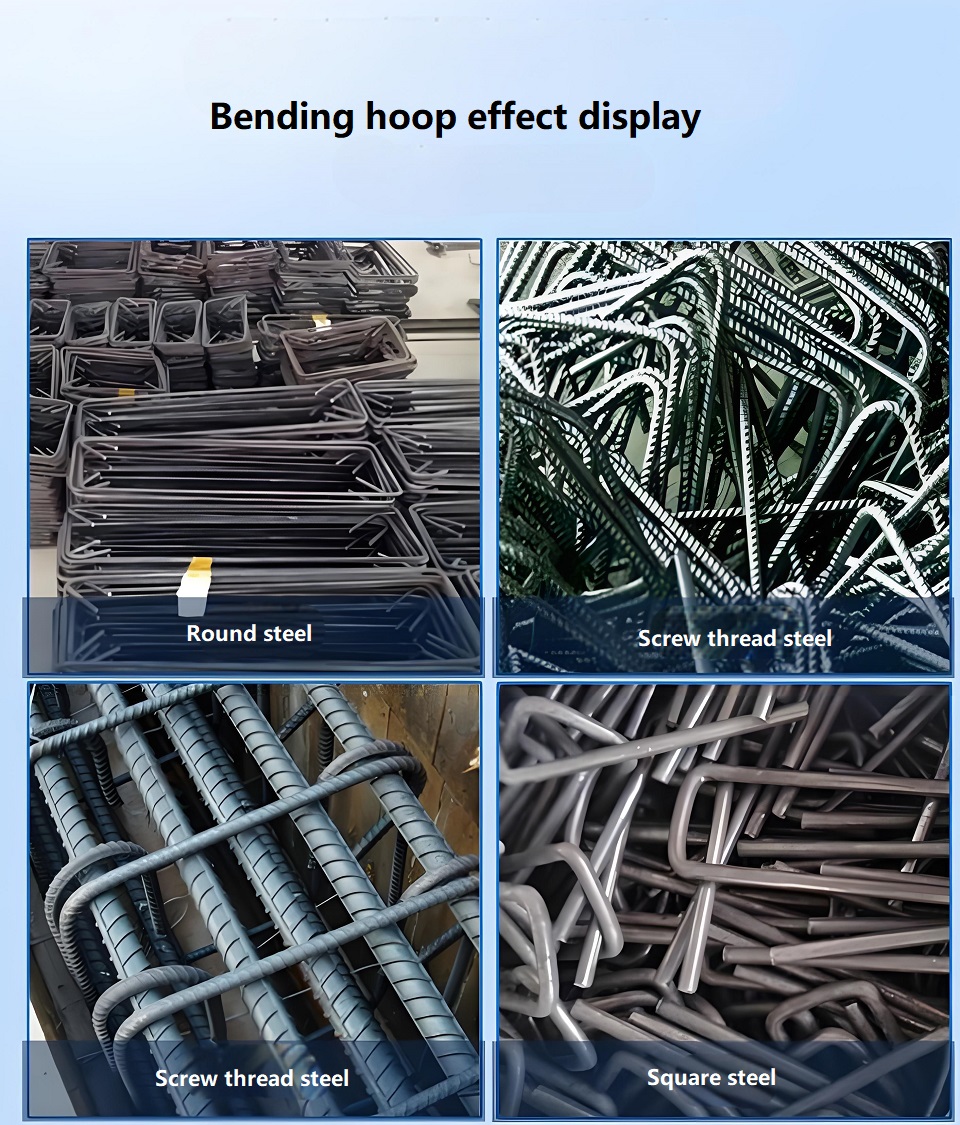

The choice between a bending machine or a hoop bending integrated machine depends on specific usage needs and scenarios. Bending machine is a type of steel processing machinery, whose working mechanism is a horizontal working disc that rotates on a vertical axis. By placing the steel bars in specific positions and fixing them on the machine tool using support pins, the central pin axis and bending pin axis are mounted on the working disc, and the steel bars are bent when the disc rotates. This machine is suitable for bending steel bars of various diameters. The bending pin shaft is inserted through the holes on the working plate, and the center pin shaft of different diameters can be replaced accordingly to adapt to steel bars of different diameters.

The hoop bending machine, also known as the straightening and bending hoop machine, is a machine that can automatically bend hoop reinforcement and has technical content. It combines the functions of wire drawing machine and bending hoop machine, mainly used for automatic bending hoop reinforcement.

When choosing which machine to use, the following points need to be considered:

● Application scenario: If a large amount of steel bar bending work needs to be carried out on a construction site, especially when bending steel bars of different diameters, a bending machine is a good choice. It can adapt to different diameter requirements by replacing different pin shafts to meet different work needs.

● Functional requirements: If a machine is needed to simultaneously complete the functions of straightening and bending hoops, then a hoop bending integrated machine may be more suitable. This machine can automatically perform bending operations and is suitable for production environments that require high efficiency and automation.

●Economy: Consider the cost of purchasing and maintaining. If the budget is limited, it may be necessary to choose a more economical solution. At the same time, the cost-effectiveness of long-term use should also be considered, including factors such as electricity consumption and maintenance costs.

Main Technical Parameters:

| Parameter | GF20 | GF25 | GF28 |

|---|---|---|---|

| Machine Model | GF20 (numerical control version) | GF25 (numerical control version) | GF28 (numerical control version) |

| Bending Speed | 20 - 25 times/min | 25 - 28 times/min | 25 - 30 times/min |

| Motor Power | 3kw | 3kw | 3kw |

| Power Supply Voltage | 380V | 380V | 380V |

| Machine Weight | 90kg | 120kg | 160kg |

| Bending Range | 4 - 20mm | 4 - 25mm | 4 - 28mm |

| Motor Rotational Speed | 1440r/min | 1440r/min | 1440r/min |

| Rated Frequency | 50Hz | 50Hz | 50Hz |

| Overall Dimension | 800X530X830mm | 850X570X900mm | 900X600X900mm |

Our company also offers other models, welcome to negotiate by email.